TATKRAKHMALPATOKA JSC

Our factory

Tatkrakhmalpatoka JSC factory is equipped with the latest cutting-edge equipment. Manufacturing process management is centralized from a single operator’s room. Fully automatized process allows exclude the influence of the human factor on the stability of product quality. The equipment allows producing any types of grain extracts depending on the selected program and the initial raw materials.

We use various kind of grain as raw material – rye, barley, corn etc. Our equipment reproduces at up-to-date level the traditional technologies of grain processing that dating back thousands of years. The human’s use of such processes as fermentation of malt, saccharification of the starch, filtering of mash goes back for thousands years to the first attempts of conscious use of food technologies. Our goal is to preserve all valuable substances of the source grain in the product during processing by applying advanced technologies without the use of chemical additives and preservatives. As a result, we get a variety of cereal extracts for producing beverages on a natural basis, replacing usual white sugar in bakery and confectionery industry and for the production of healthy food.

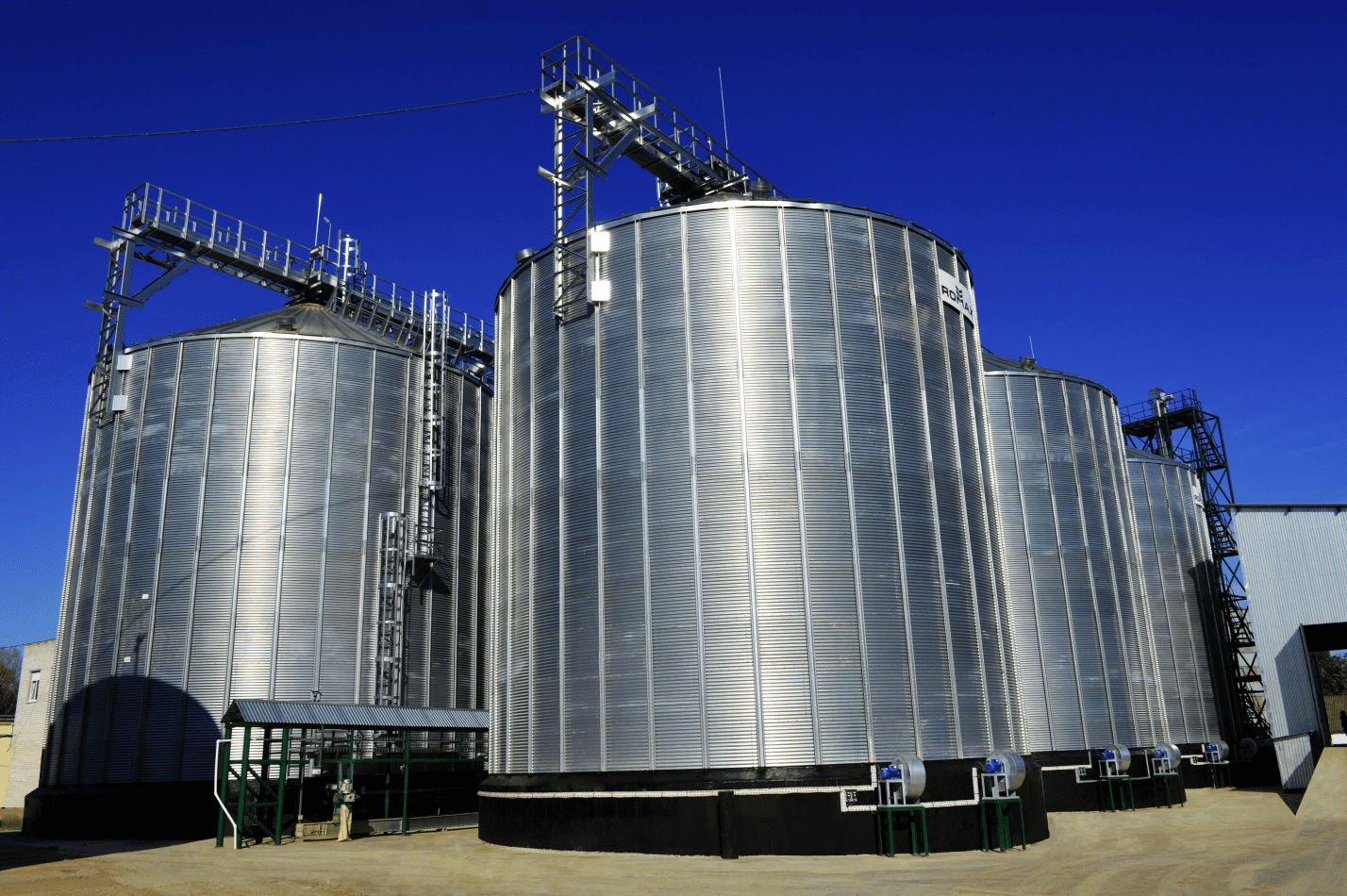

Grain acceptance is performing in the elevator complex that allows drying and conditioning the grain. All processes of transportation, conditioning and control of grain are fully automated. The elevator gives the opportunity to stabilize the supply of raw materials to the factory and not be dependent on seasonal fluctuations in prices and the scope of supply in the grain market.

Grain and malt are milled in a ventilated hammer mill specially designed for brewing and the production of kvass wort. The use of such hammer mill allows precisely control the dimensions of the grinding in order to achieve the best results in a brew house.

On the next step the milled mass goes to Mechamasher which allows to mix different types of grain and malt grindings with water at a low mash ratio and to minimize the contact with air that provides smooth pumping of mash in mash tanks.

Water treatment system with the use of reverse osmosis allows excluding the influence of water quality on the stability of product parameters.

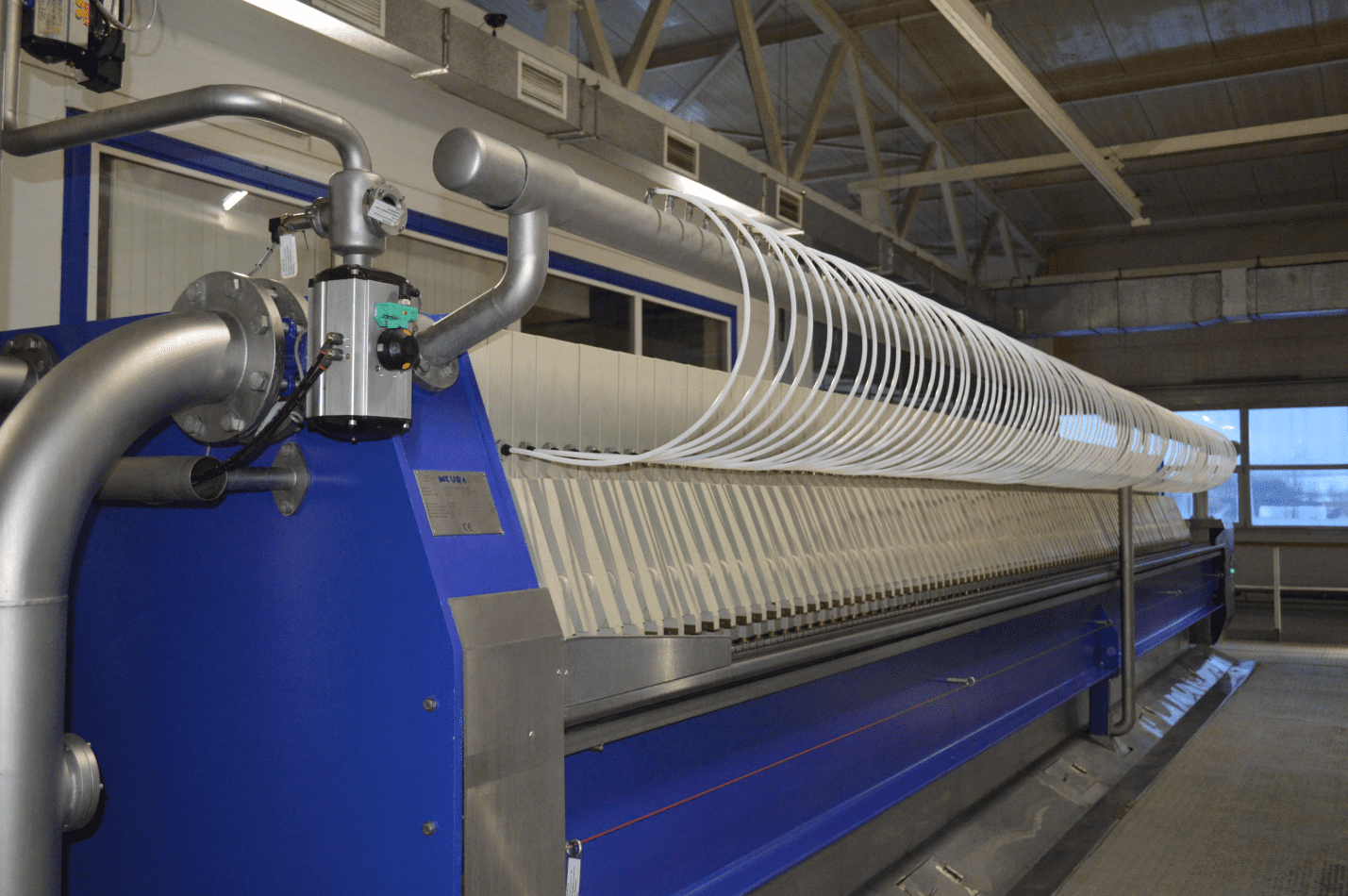

Filtration process is the separation of the wort from the spent grains, is the most important part of the brewing, which has a significant impact on the final quality of the product and the efficiency of the brewing process.

The MEURA 2001 Hybrid Mashfilter on our factory allows achieving the following benefits simultaneously:

-

High capacity - up to 12 brews per day in a fully automated mode;

-

The production of transparent high quality wort with a low fatty acid content;

-

High yield of the extract;

-

Reduced oxidation of the product due to the air-tightness of filter chambers.

Boiling of the wort for removing of excess moisture and standardization of degrees Brix is produced on film evaporation machines the main advantage of which is the short time when evaporated solution contacts with the heated surface, which allows us to produce concentration of solutions sensitive to high temperatures. Also the film evaporation process allows to avoid the wort scorching with formation of insoluble particles and it has a positive effect on the filtration in the production process on customer’s equipment.

All equipment is undergo to weekly automatic CIP-washing with a usage of recycled washing solution after filtration or before changing type of the product which minimizes the ecological damage to the environment.

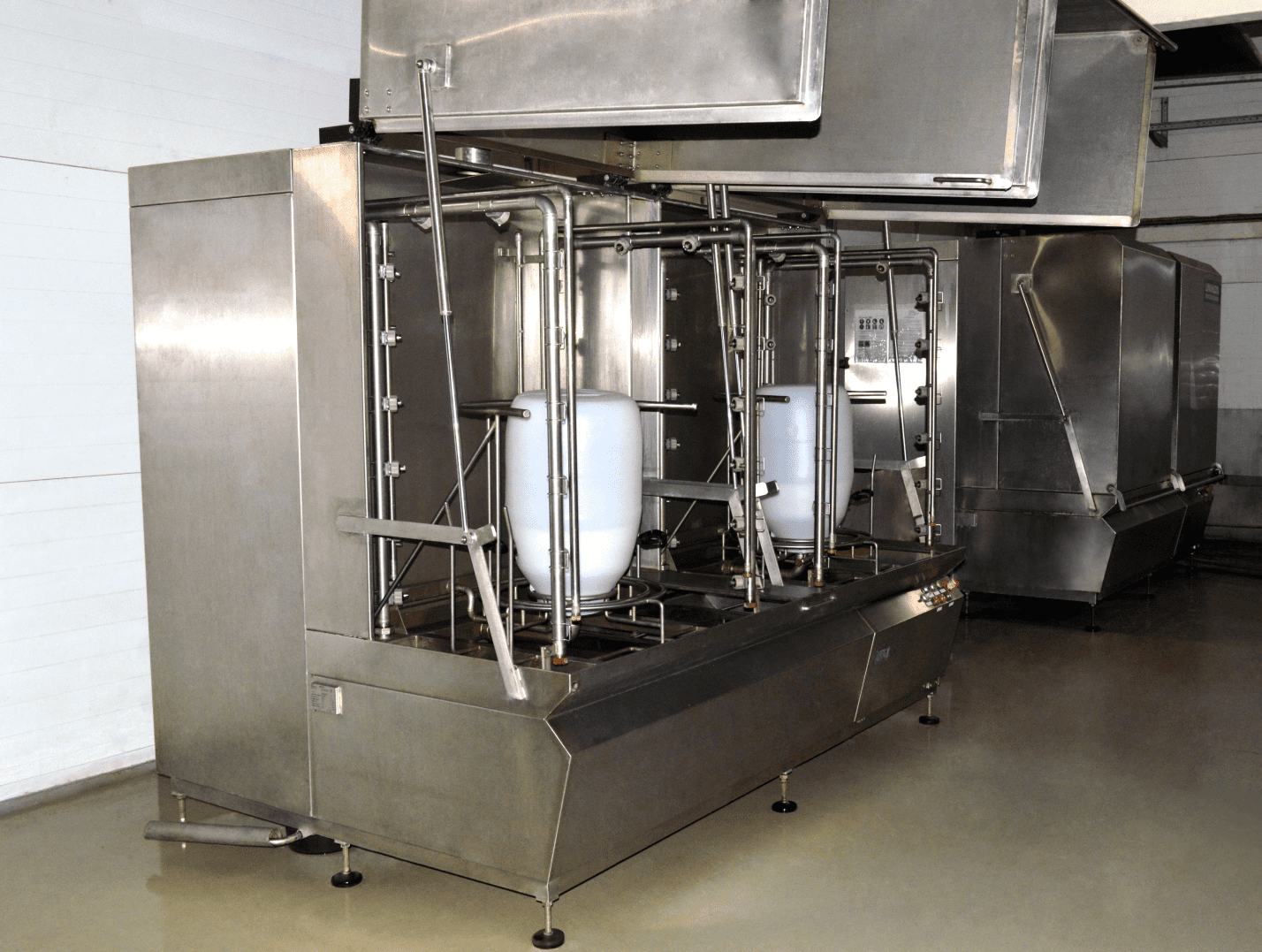

The goods are packed in plastic or metal barrels and container. Plastic barrels are steamed and washed in the Unikon cycling washer.

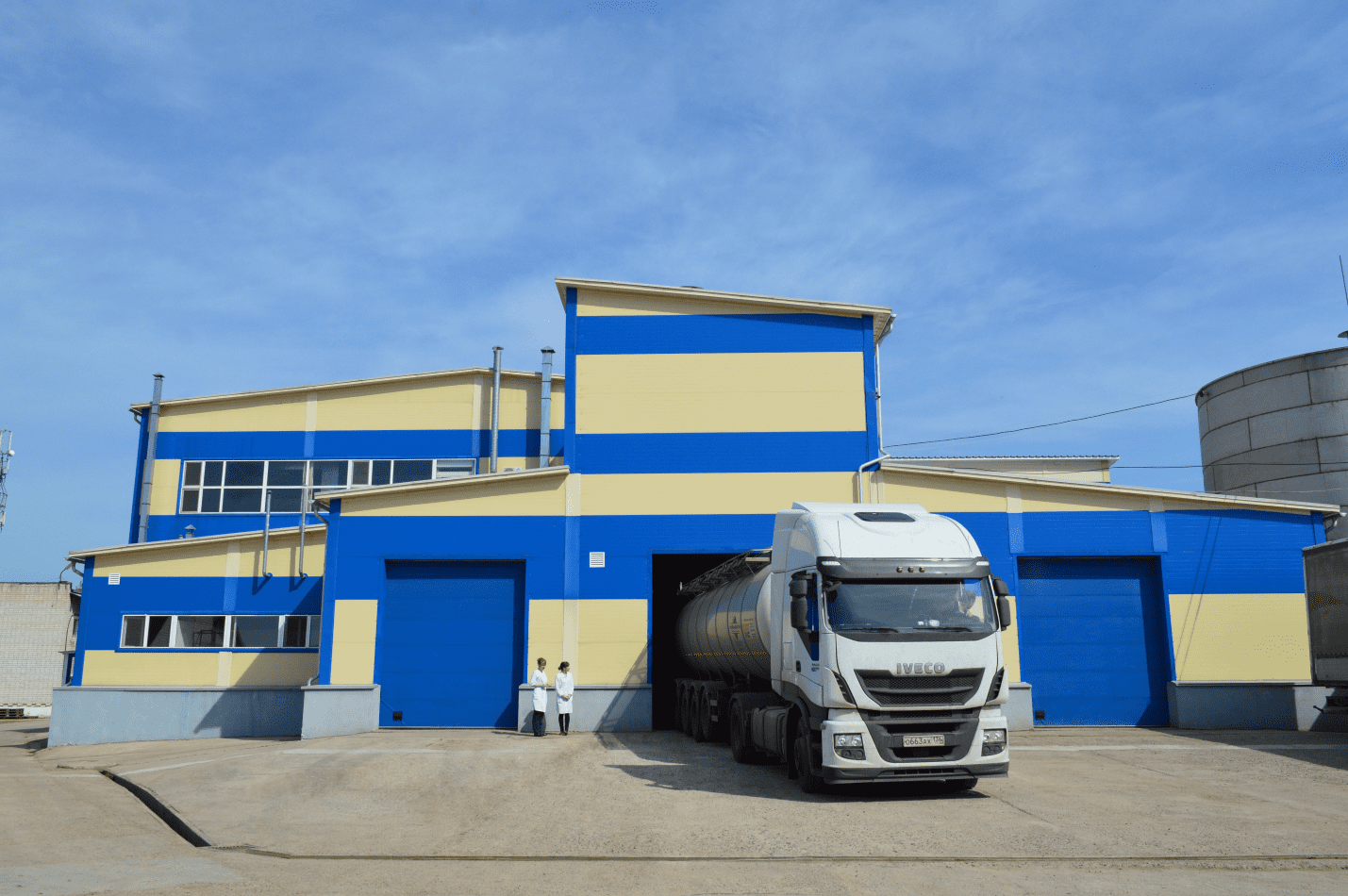

Washing, steaming and filling of truck-tankers are conducted in a special inner box to avoid the penetration of sediments and outdoor dust to the tank.